Contact

+45 4525 5884

+45 2545 9023

+45 2545 9022

calibration at the nanometer scale

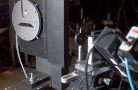

Performing calibrations from the micrometre scale down to the nanometre scale requires dedicated measurement equipment and professional expertise.

DFM is a world leader in the calibration of periodic structures such as steps and 1D and 2D lattice gratings. All measurements are traceable to a primary standard for length. The measurement microscope is equipped with laser interferometers and has a lateral measurement range of approximately 500 µm x 500 µm.

When expertise and comprehensive data matter

Based on DFM’s long term experience in the field of nanometrology, we can meet companies’ requirements in an efficient and effective manner, providing accurate measurements and detailed analysis.

“When we face a metrological challenge which we cannot solve ourselves, DFM has always been able to help us. DFM has the expertise, the equipment and service mindedness to share their knowledge in order to guide many Danish companies, such as NIL Technology, to become a leading player on the international market for nano technology”. Brian Bilenberg, CTO and Founder, NIL Technology

Product information and prices

Our price list is found here.

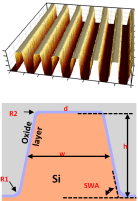

Geometrical characterization of silicon line gratings

DFM masters leading-edge scatterometry technology to measure the essential parameters for silicon line gratings. Now, we offer a new service to characterize silicon line gratings, expressed in terms of line width (CD), height and sidewall angle. The service is traceable to primary angle and wavelength standards.

The technique combines scatterometry with advanced computer processing to obtain very attractive levels of uncertainty. The technique does not have the dimensional limitations of microscope technologies, such as AFM or SEM.

In this table we show an example of a measurement of the parameters including the uncertainties shown in the figure. The uncertainty will depend on the actual specimen. Feel free to contact us for further information, or for a quotation.

Step height calibration

Calibration of step height is performed with an Atomic Force Microscope (AFM).

The measurements are traceable to the international system of units, SI, andd is DANAK accredited (accreditation nr. 255).

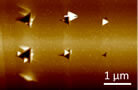

Calibration of 2D lattice periodicity

The calibration of periodicity in 2D lattice structures is performed with an Atomic Force Microscope (AFM).

The measurements are traceable to the international system of units, SI, and is DANAK accredited (accreditation nr. 255).

Optical characterization of film thickness and refractive index of multilayered thinfilms

Ellipsometric characterization of film thickness and refractive index for multilayered thinfilms.

The uncertainty is less than 0.5% for both parameters.

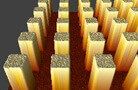

Young's modulus and hardness at the nano scale

DFM measures Young’s modulus (the modulus of elasticity) and hardness of the outermost nanometers (typically 1 - 100 nm) of surfaces by using AFM, Atomic Force Microscopy.

DFM is even able to measure minute particles, such as powders, or very fine coatings.

Microadhesion measurements

DFM measures adhesion of surfaces and micro- and nano-sized particles by means of atomic force microscopy (AFM). Sharp AFM probes enhance the imaging resolution, whereas spherical AFM probes give more accurate measurements. Also, spherical probes allow a wider selection of probe materials.n.

Our measurements are done under ambient conditions, in either air or liquid. Read more in our product sheet.

Microcrystal measurements

DFM may characterize the structural stability of micro crystals’ surfaces under environmental conditions (temperature and humidity) using AFM.

For further details, please read more in our product sheet.

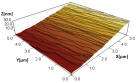

Measurement of roughness

Measurement of surface roughness over a range of up to 500 μm and amplitudes less than 5 μm.

The magnitude of roughness can be measured down to the atomic scale (< 1 nm).

These measurements aid quality control processes and check that specifications have been met for components such as micromechanical and microoptical components, including lab on a chip.

Roughness measurements are also valuable for finely polished surfaces used in demanding applications, such as injection molding of components for use in medical diagnostic, the pharma industry, etc.

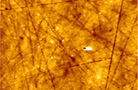

Measurement of the profile of optical lattices

Apart from the lattice period and step height, DFM can measure the fill factor, as well as line width, side wall angle and side wall roughness.

These accurate measurements of optic profiles can be used to further optimise their optical function and the final quality control.