roughness and hole plates

In addition to the calibrations using interferometry DFM offers tactile calibrations and tests of roughness meters, roughness standards, and hole plates. Through these services, DFM covers the surface characterizations that are of particular importance to the production industry.

Accredited calibration of roughness meters

DFM calibrates all kinds of roughness meters, with traceability to the international system of units, SI. DFM offers different types of calibrations as the design of each roughness meter determines which calibration is appropriate.

DFM carries out three kinds of calibrations: Parameter, amplification, and total calibration. For each of these three the calibrations are done for a specific choice of stylus and amplification setting. The calibrations are carried out at DFM’s laboratories in Hørsholm, Denmark. For companies located in Denmark, DFM may carry out on-site calibrations. Please contact us further details.

We offer a choice of calibration with or without adjustment: With an adjustment the roughness meter will show the correct value, though the electronics of the meter may age or drift after the adjustment. Without an adjustment, a set of correction factors will have to be applied, but the roughness meter may be less susceptible to the aging or drift that otherwise could be the result of an adjustment. Please contact us if you would like to discuss your options.

Further information of roughness meters is found here.

Accredited calibration of roughness standards

Roughness standards are used for the calibration of roughness meters. DFM carries out accredited calibration of roughness standards with traceability to the international systems of units, SI. The different types of roughness standards are described in DS/ISO 5436-1:

- Type A is used for checking the vertical amplification for profile measuring instruments with a vertically measuring stylus

- Type B is used for checking the condition of a stylus

- Type C is primarily used for checking instruments that register roughness parameters

- Type D is used for the verification of an instrument’s calibration

DFM is accredited to calibrate the following standardized artefacts:

- ISO type A1: Wide grooves with flat bottoms (2 grooves)

- ISO type A2: Wide grooves with rounded bottoms (6 grooves)

- ISO type B2: Groove patterns on a common base

- ISO type C1: Grooves with a sine wave profile

- ISO type C2: Grooves with an isosceles triangular profile

- ISO type C3: Artefact that simulates approximate sine wave grooves

- ISO type C4: Grooves with an arcuate profile

- ISO type D: Irregular profile in one direction

Lowest measurement uncertainty: 1 % of the parameter value

Read more about calibration of roughness standards here.

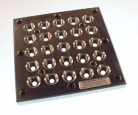

Accredited calibration of hole plates

Opto-mechanical hole plates are used for the calibration of eg. coordinate measuring machines, profile projectors and measuring microscopes.

The reference elements in the hole plate are sharply edged holes in a thin metal plate mounted in a rigid steel frame. The picture shows an example of a hole plate developed by IPU at the Technical University of Denmark (DTU).

DFM offers accredited calibration of hole plates according to a German DKD-guideline. The tests are carried out by measuring all the holes in the plate, after the so called reversal method, followed by a comparator measurement whereby traceability is transferred with the help of a calibrated zerodur hole plate.

Find more information about our hole plate calibrations here.

Accredited testing of surface characteristics

DFM measures the surface characteristics of internal and external surfaces by using a calibrated roughness meter. Structures between 0.05 μm and 400 μm can be charaterized. The processing of the profile data can be done according to a number of different methods to support different analyses.

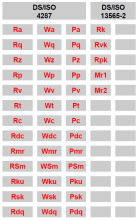

By measuring the surface characteristics DFM may calculate the various standardized R-, W and P parameters in DS/ISO 4287 as shown in the table.

The roughess parameters are calulated using a Gauss filter in accordance with DS/ISO 11562. DFM can carry out a spectral analysis of the profile data in case time-related phonomena are of importance.

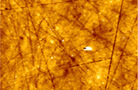

Measuring roughness at the nano scale

If you are looking for measurements of surface roughness down to the atomic scale (< 1 nm) DFM can help. This can be done for surfaces over a length up to 500 µm and amplitudes less than 10 µm.

Such measurements can be used for eg. quality control and for the characterization of micromechanical components, like a lab on a chip. Also the measurements can be used to characterize delicately polished surfaces of tools used for the production of mission-critical or life-supporting components.

Product information and pricing

You may find our price list here.